From Factory to Flutter: The Step-by-Step Journey of Eyelash Extensions ✨

Share

Eyelash extensions may look delicate, but behind every lash tray is a carefully controlled process. Each step combines hygiene, precision, and craftsmanship to make sure the lashes you wear are lightweight, safe, and absolutely beautiful.

Here’s a closer look at the fascinating journey:

Step 1: Hygiene First 🧴

Before a single lash is touched, workers must disinfect themselves. Hands, clothing, and even shoes are sanitized before entering the workshop. This keeps the production area spotless, ensuring that every lash is made in a clean and safe environment.

👉 Think of it as a beauty “clean room” — where lashes begin their journey in purity.

Step 2: Pressing the Fibers 🌱

The story begins with rolls of PBT fiber, the premium material used in lash extensions. These fibers are carefully pressed and aligned according to their length. This step smooths the fibers, removes irregularities, and prepares them for cutting.

Every detail matters here — consistency at this stage means lashes will look uniform and natural later.

Step 3: Cutting to Size ✂️

Once pressed, the fibers are cut into precise lengths — ranging from short, subtle lashes (around 6–8mm) to long, dramatic ones (up to 20mm).

This stage is all about customization. The variety of lengths ensures lash artists can create anything from a “barely-there natural” look to a bold “red-carpet” eye.

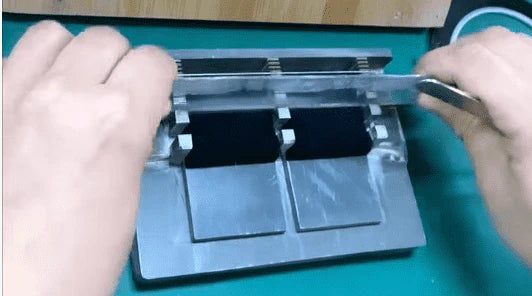

Step 4: Curl & Heat Set 🔥

Here’s where the magic happens. The lashes are rolled around special curl rods and set under heat. This “baking” process locks in the curl, whether it’s a natural C curl or a bold D curl, so your lashes hold their shape beautifully.

Just like baking, the time and temperature must be perfect. This process “locks in” the curl, so it lasts through weeks of wear.

Step 5: Arranging on Label Cards ✨

Freshly curled lashes are then hand-arranged onto label cards. Each lash is placed neatly in rows, making it easy for lash artists to pick them up with tweezers during application.

This step requires patience and precision — imagine arranging hundreds of tiny lashes so they line up flawlessly.

Step 6: Chic Packaging 📦

Once the label cards are ready, they’re carefully placed into sleek lash boxes. The packaging doesn’t just protect the product — it also makes the lashes look professional and beautiful the moment the box is opened in a salon.

For many lash artists, this is the first impression of quality.

Step 7: Final Inspection ✅

Before any lash tray is shipped, it must pass a thorough inspection. Workers check for:

Consistency in curl

Smooth lash tips (no splitting or rough edges)

Even lengths and thickness

Easy lash pickup from the strip

Only the trays that meet all standards are approved for shipping.

From Clean Room to Your Eyes 💖

By the time your lash artist opens a tray, those tiny fibers have already gone through seven detailed steps of hygiene, precision, and artistry.

So next time you flutter your lashes in the mirror, remember — they’ve traveled a long journey from a clean factory floor to becoming the finishing touch on your look.